的溫升 (5)、當(dāng)停止水泵運(yùn)轉(zhuǎn)時(shí) (6)、長(zhǎng)期停止使用時(shí) 2 (1)、水泵軸承最高溫度不應(yīng)超過(guò)75℃ (2) (3) (4) (5)、運(yùn)轉(zhuǎn)過(guò)程中,如發(fā)現(xiàn)噪音或其他不正常的聲音時(shí),應(yīng)立即停車,檢查原因,加以消除;

(6) |

running

speed is normal, and then open gradully the brake valve untitl the suction water

of the two sides reaehs to balance.

4. Screw homogenizenously the nuts

on the primp packing gland so as to the leakage of liquid is little, at the

same time, pay more attention to the packing ease temperature rising.

5. While stopping the pump runing,

first turn off the cocks of the vacuum gauge and manometer and turn off the

brake valve on the discharge pipe passage way. ff the ambient temperature is

low, the coach un- der the pump casing should be loosen to drain away the rest

water so as to keep the pump easing from being split by frost.

6. ff it will not be used for a long

time, the pump must be disconnected and all the parts should be kept dring, and

smear the machining face with rust - proof

grease

oil.

Running:

1. The temperature of the pump

bearing should not be exceeded 75℃.

2. The suitable quantity of the

good Ca-bade grease which is used to lubricate the bearing occupies 1/3 to 1/2

space of the bearing body, and it should be changed periodicaly.

3. When the paking worn, tighten the packing gland properly or

change it if it is necessary.

4. Check the flexible coupling part, care

more for the motor bearing temperature rising.

5. During running, if any noise or unnormal sounds are

h,eared, stop the pump immediately, and look for the cause, then clear out.

6. It is not allowed to increase

the running speed wantonly, but you can decrease the running speed of the pump

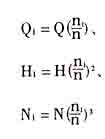

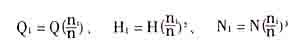

for working, The performance Paramet of the pump changes as the following.

(Plese see the formula as follow) :

|